Gears are mechanical parts with teeth that can be matched with each other. Gear transmission can complete functions such as deceleration, speed increase, and direction change. It is extremely widely used in mechanical transmission and the entire mechanical field. This article summarizes the processing technology of gear parts.

?

1

Function and structure of gears

Although gears are designed in different shapes and sizes due to their different functions in the machine, they can always be divided into two parts: the ring gear and the wheel body. Common cylindrical gears have the following types (pictured below): disc gears, sleeve gears, internal gears, shaft gears, sector gears, racks. Among them, disc gears are the most widely used.

?

The structure of cylindrical gear

A cylindrical gear can have one or more ring gears. Ordinary single ring gears have good manufacturability; but the small ring gears of double or triple gears are often affected by the shoulder, which limits the use of certain processing methods. Generally, only gear shaping can be used. If the gears require high precision, and when gear shaving or gear grinding is required, multi-ring gears are usually made into a combined structure of single-ring gears.

2

Precision requirements for cylindrical gears

The manufacturing precision of the gear itself has a great influence on the working performance, carrying capacity and service life of the entire machine. According to the use conditions of gears, the following requirements are put forward for gear transmission:

1. Motion accuracy

It is required that the gear can accurately transmit motion, and the transmission ratio is constant, that is, the angle error of the gear should not exceed a certain range during one revolution.

2, Work stability

The gear transmission is required to move smoothly, and the impact, vibration and noise should be small. This requires limiting the change of the instantaneous speed ratio when the gear rotates, that is, limiting the rotation angle error in a short period.

3. Contact accuracy

When the gear is transmitting power, in order not to cause excessive contact stress due to uneven load distribution and cause premature wear of the tooth surface, this requires uniform tooth surface contact when the gear is working, and ensures a certain contact area and meets the requirements. position.

4. Tooth side clearance

When gear transmission is required, a certain gap is left between the non-working tooth surfaces to store lubricating oil and compensate for dimensional changes caused by temperature and elastic deformation and some errors in processing and assembly.

3

Gear material

Gears should be made of suitable materials according to the working conditions used. The choice of gear material has a direct impact on the processing performance and service life of the gear.

Generally, medium-carbon steel (such as 45 steel) and low- and medium-carbon alloy steel such as 20Cr, 40Cr, 20CrMnTi, etc. are used for gears. Important gears with higher requirements can be made of 38CrMoAlA nitrided steel, and non-transmitting gears can also be made of materials such as cast iron, bakelite or nylon.

4

Heat treatment of gears

According to different purposes in gear processing, two heat treatment processes are arranged:

1. Blank heat treatment

Before and after the tooth blank is processed, pre-heat treatment is arranged for normalizing or quenching and tempering. The main purpose is to eliminate the residual stress caused by forging and rough machining, improve the machinability of the material and improve the comprehensive mechanical properties.

2. Tooth surface heat treatment

After the tooth profile is processed, in order to improve the hardness and wear resistance of the tooth surface, heat treatment processes such as carburizing and quenching, high frequency induction heating and quenching, carbonitriding and nitriding are often carried out.

5

Gear blank

The rough forms of gears mainly include bars, forgings and castings. Bar stock is used for gears with small size, simple structure and low strength requirements. When gears require high strength, wear resistance and impact resistance, forgings are often used. Gears with a diameter greater than 400-600mm are often cast blanks.

In order to reduce the amount of machining, gear teeth can be cast directly for large-size and low-precision gears; for small-size and complex-shaped gears, precision casting, pressure casting, precision forging, powder metallurgy, hot rolling and cold extrusion can be used. The process produces tooth blanks with gear teeth to improve labor productivity and save raw materials.

6

Selection of machining plan for tooth blank

For the tooth blanks of shaft gears and sleeve gears, the machining process is basically similar to that of general shafts and sleeves. Now we mainly discuss the machining process of disc gears. The processing plan of the tooth blank mainly depends on the wheel structure and production type of the gear.

1. Machining of gear blanks for mass production

When a large number of medium-sized gear blanks are processed in large quantities, the process of "drilling, pulling, and multi-tool turning" is often used.

(1) Drilling or reaming is performed by positioning the outer circle and end surface of the blank.

(2) Pull holes.

(3) Use the hole to locate the outer circle, end face, grooving and chamfering on a multi-tool semi-automatic lathe.

This kind of technological scheme adopts high-efficiency machine tools to form an assembly line or an automatic line, so the production efficiency is high.

2. Batch production of gear blank processing

When producing gear blanks in batches, the process of "car-pulling-car" is often used

(1) Position the outer circle, end face and inner hole of the tooth blank or wheel.

(2) The pull hole (or spline hole) is supported by the end face.

(3) Use holes to locate the outer circle and end face of the fine turning.

This kind of scheme can be realized by horizontal lathe or turret lathe and broaching machine. It is characterized by stable processing quality and high production efficiency.

When the tooth blank hole has a step or the end face has a groove, you can make full use of the multi-tool on the turret lathe for multi-station processing, and complete the tooth blank processing at one time on the turret lathe.

7

Gear tooth processing method

The tooth profile processing of the gear ring is the core of the entire gear processing. There are many processes in gear processing, all of which serve for tooth profile processing. The purpose is to obtain gears that meet the accuracy requirements.

According to the processing principle, the tooth profile can be divided into forming method and generating method. The forming method is a method of cutting the tooth surface with a forming tool that matches the shape of the tooth groove of the gear to be cut, such as tooth milling, tooth pulling, and forming tooth grinding.

The generative method is a method in which the gear cutter and the workpiece perform a generative motion to cut out the tooth surface according to the meshing relationship of the gear pair, such as gear hobbing, gear shaping, gear shaving, gear grinding and honing.

The choice of tooth profile machining plan mainly depends on the gear's precision grade, structure shape, production type and production conditions. For gears of different precision grades, the commonly used tooth profile machining plans are as follows:

(1) Gears with accuracy below grade 8

The hardened and tempered gear can meet the requirements with gear hobbing or gear shaping. For hardened gears, a machining plan of rolling (shaping) teeth-tooth end processing-quenching-correction hole can be used. However, the machining accuracy of the tooth profile should be improved by one level before quenching.

(2) 6-7 grade precision gear

For hardened gears, the following can be used: rough hobbing-fine hobbing-tooth end machining-fine shaving-surface hardening-correction reference-honing.

(3) Gears with accuracy above grade 5

Generally used: rough gear hobbing-fine gear hobbing-tooth end machining-quenching-calibration standard-rough gear-fine gear. Gear grinding is the machining method with the highest precision in tooth profile machining and the smallest surface roughness value. The highest precision can reach 3-4.

1. Milling teeth

Gear accuracy grade: below 9

Tooth surface roughness Ra: 6.3~3.2μm

Scope of application: processing low-precision external cylindrical gears, racks, bevel gears, and worm gears in single-piece repair production

2. Pull teeth

Gear accuracy grade: 7

Tooth surface roughness Ra: 1.6~0.4μm

Scope of application: mass production of 7-level internal gears, external gear broaches are complicated to manufacture, so use less

3. Hobbing

Gear accuracy grade: 8~7

Tooth surface roughness Ra: 3.2~1.6μm

Scope of application: processing medium-quality external cylindrical gears and worm gears in various mass production

4. Shaping

Gear accuracy grade: 8~7

Tooth surface roughness Ra: 1.6μm

Scope of application: processing medium-quality internal and external cylindrical gears, multiple gears and small racks in various mass production

5. Rolling (or inserting) teeth-quenching-honing

Gear accuracy grade: 8~7

Tooth surface roughness Ra: 0.8~0.4μm

Scope of application: gears used for tooth surface quenching

6. Hobbing-Shaving

Gear accuracy grade: 7~6

Tooth surface roughness Ra: 0.8~0.4μm

Scope of application: mainly used for mass production

7. Hobbing-shaving-quenching-honing

Gear accuracy grade: 7~6

Tooth surface roughness Ra: 0.4~0.2μm

Scope of application: mainly used for mass production

8. Rolling (inserting) teeth-quenching-gear grinding

Gear accuracy grade: 6~3

Tooth surface roughness Ra: 0.4~0.2μm

Scope of application: used for tooth surface processing of high-precision gears, with low productivity and high cost

9. Rolling (inserting) teeth-grinding teeth

Gear accuracy grade: 6~3

Tooth surface roughness Ra: 0.4~0.2μm

Scope of application: used for tooth surface processing of high-precision gears, with low productivity and high cost

8

Tooth end processing

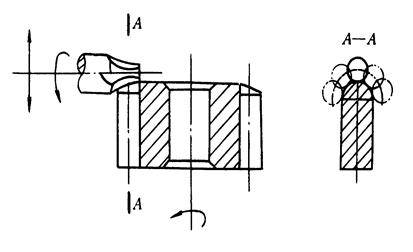

The tooth end of the gear can be processed with rounding, chamfering, chamfering and deburring, as shown in the figure below. The rounded and inverted gears are easy to enter the meshing state when shifting gears, reducing impact. Chamfering can remove the sharp edges and burrs of the tooth end.

?

Tooth end processing

a) Round b) Inverted tip c) Chamfer

The following figure is a schematic diagram of rounding the tooth end with a finger milling cutter. When rounding, the milling cutter rotates at a high speed and swings along an arc. After one tooth is processed, the workpiece retreats from the milling cutter. After indexing, the milling cutter quickly approaches the tooth end of the next tooth. Tooth end processing must be done before gear quenching, usually after gear rolling (shaping) and before gear shaving.

?

Round tooth end

9

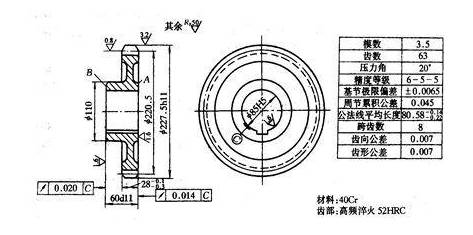

Straight tooth cylindrical gear machining process

?

High precision gear

1. Blank forging

2. Normalizing heat treatment

3. The shape of the rough turning, leaving a machining allowance of 2mm everywhere

Positioning datum: outer circle and end face

4. In the fine turning, the inner hole is to Φ84.8H7, the total length is 0.2mm, and the rest is to size

Positioning datum: outer circle and end face

5. Inspection

6. Hobbing the tooth surface, leaving a grinding allowance of 0.25~0.3mm

Positioning datum: inner hole and end face A

7. Chamfer

Positioning datum: inner hole and end face A

8. Fitter deburring

9. Tooth surface induction hardening HRC52

10. Key slot

Positioning datum: inner hole and end face A

11. Rely on grinding large end face A

Positioning datum: inner hole

12. Grind surface B to total length

Positioning datum: end face A

13. Grind the inner hole to φ85H5

Positioning datum: inner hole and end face A

14. Tooth surface grinding

Positioning datum: inner hole and end face A

15. Inspection

10

Analysis of gear machining process

1. Selection of positioning datum

The selection of the gear positioning datum is often different due to the different structure and shape of the gear. Gears with shafts mainly use top positioning, and cone plugs are used when the aperture is large. The precision of the top positioning is high, and the benchmark can be unified. Gears with holes often use the following two positioning and clamping methods when processing the tooth surface.

(1) Positioning by inner hole and end face That is, joint positioning of the inner hole and end face of the workpiece, determine the gear center and axial position, and adopt the clamping method facing the positioning end face. In this way, the positioning reference, design reference, assembly reference and measurement reference can be overlapped, and the positioning accuracy is high, which is suitable for mass production. However, the manufacturing accuracy of the fixture is relatively high.

(2) Positioning of outer circle and end face The fit gap between the workpiece and the fixture mandrel is relatively large. Use a dial indicator to correct the outer circle to determine the center position and position it on the end face; apply clamping from the other end face. This method has low production efficiency because each workpiece needs to be calibrated; it has high requirements for the coaxiality of the inner and outer circles of the tooth blank, but not high requirements for the accuracy of the fixture, so it is suitable for single-piece, small-batch production.

2. Machining of gear blanks

The gear blank processing before tooth surface processing occupies a very important position in the entire gear processing process, because the benchmarks used for tooth surface processing and testing must be processed at this stage; whether it is from improving productivity or ensuring gear processing quality , Must pay attention to the processing of gear blanks.

In the technical requirements of gears, attention should be paid to the dimensional accuracy requirements of the addendum circle, because the detection of the tooth thickness is based on the addendum circle. The accuracy of the addendum circle is too low, which will inevitably make the measured tooth thickness value impossible Reflect the size of the tooth gap.

Therefore, the following three issues should be paid attention to during this processing:

(1) When the diameter of the addendum circle is used as the measurement reference, the dimensional accuracy of the addendum circle should be strictly controlled

(2) Ensure that the positioning end face and the positioning hole or outer circle are mutually perpendicular

(3) Improve the manufacturing accuracy of the gear inner hole and reduce the clearance with the fixture mandrel